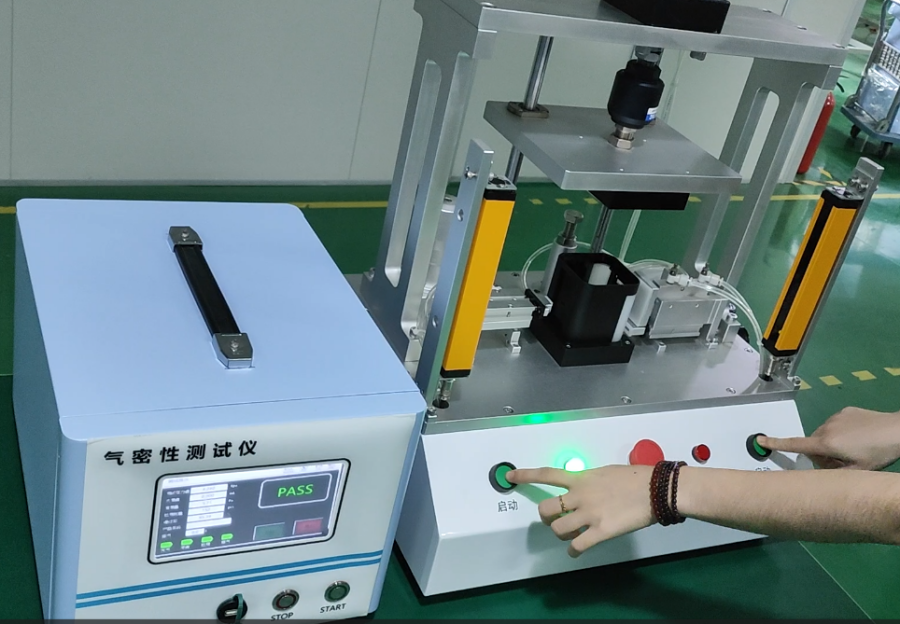

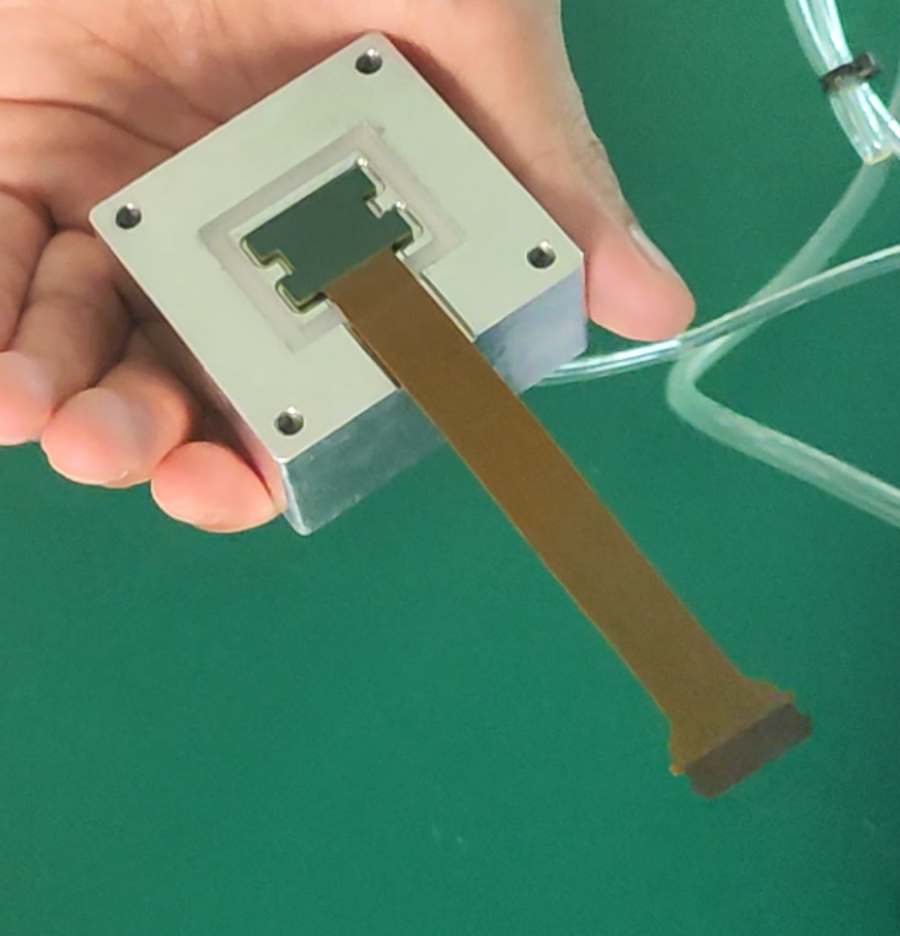

1. Outdoor doorbell air tightness test

It is used to test the air tightness of the injection molded shell of the outdoor doorbell, which is required to meet the IP67 waterproof grade requirements.

Outdoor doorbells are sometimes exposed to unobstructed places. If relevant air tightness and waterproof tests are not performed before leaving the factory, rain and other weather conditions may cause product damage.

Other injection molded products with sealing test requirements can be tested with this equipment.

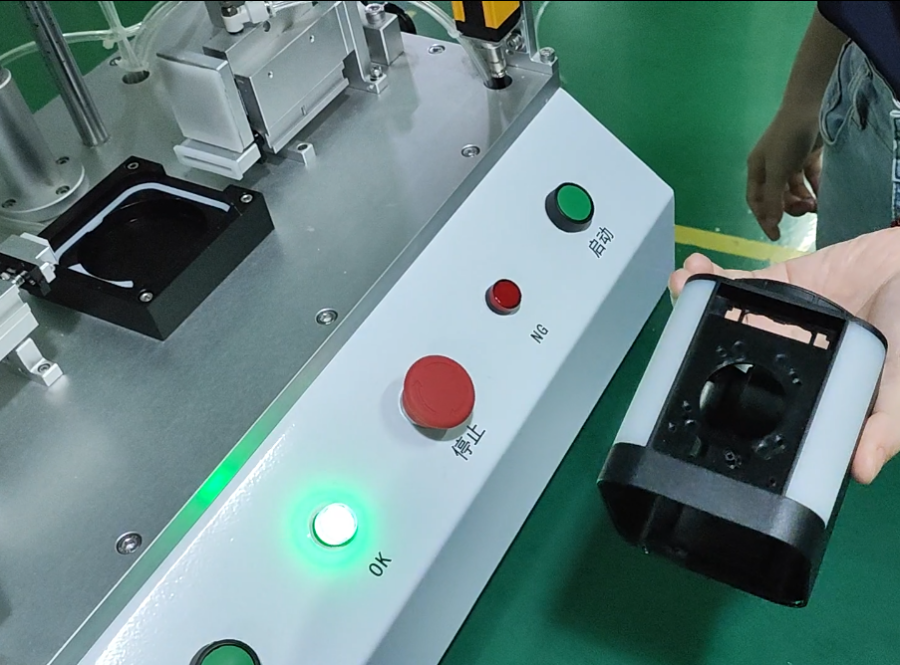

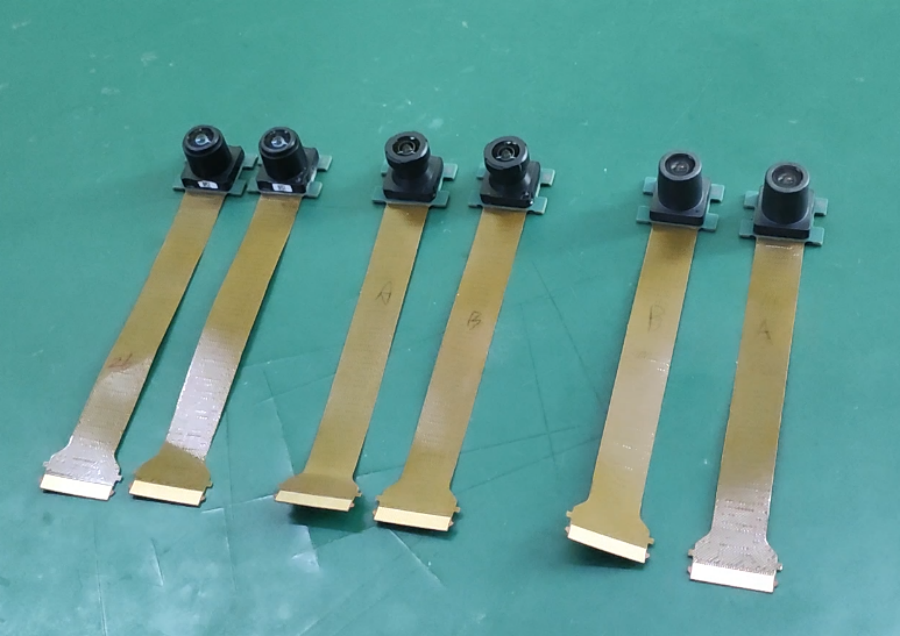

2. Air tightness test of sports camera lenses

Air tightness test equipment for sports camera lenses. It is required to meet the IP68 waterproof level requirements, and mainly detects whether the lens cover is cracked or poorly sealed to prevent water from damaging the internal components of the camera.

Other lens products can be tested for air tightness with this equipment.

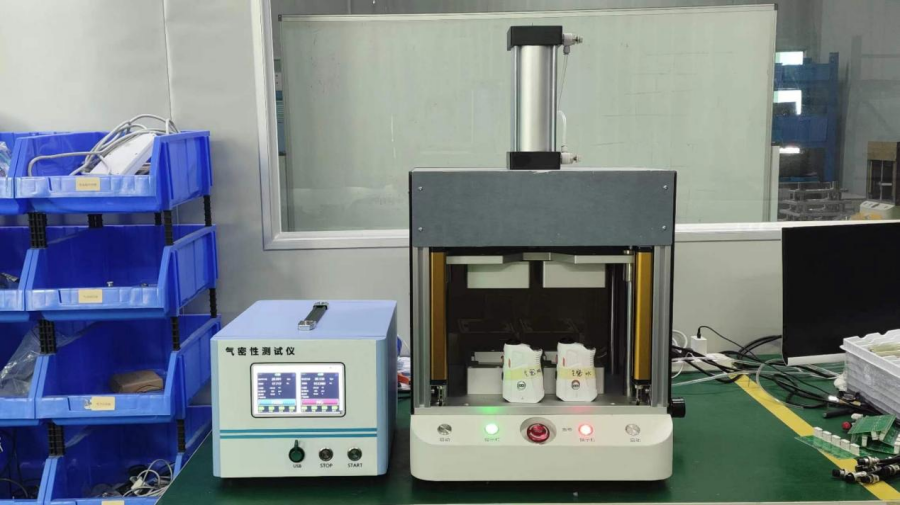

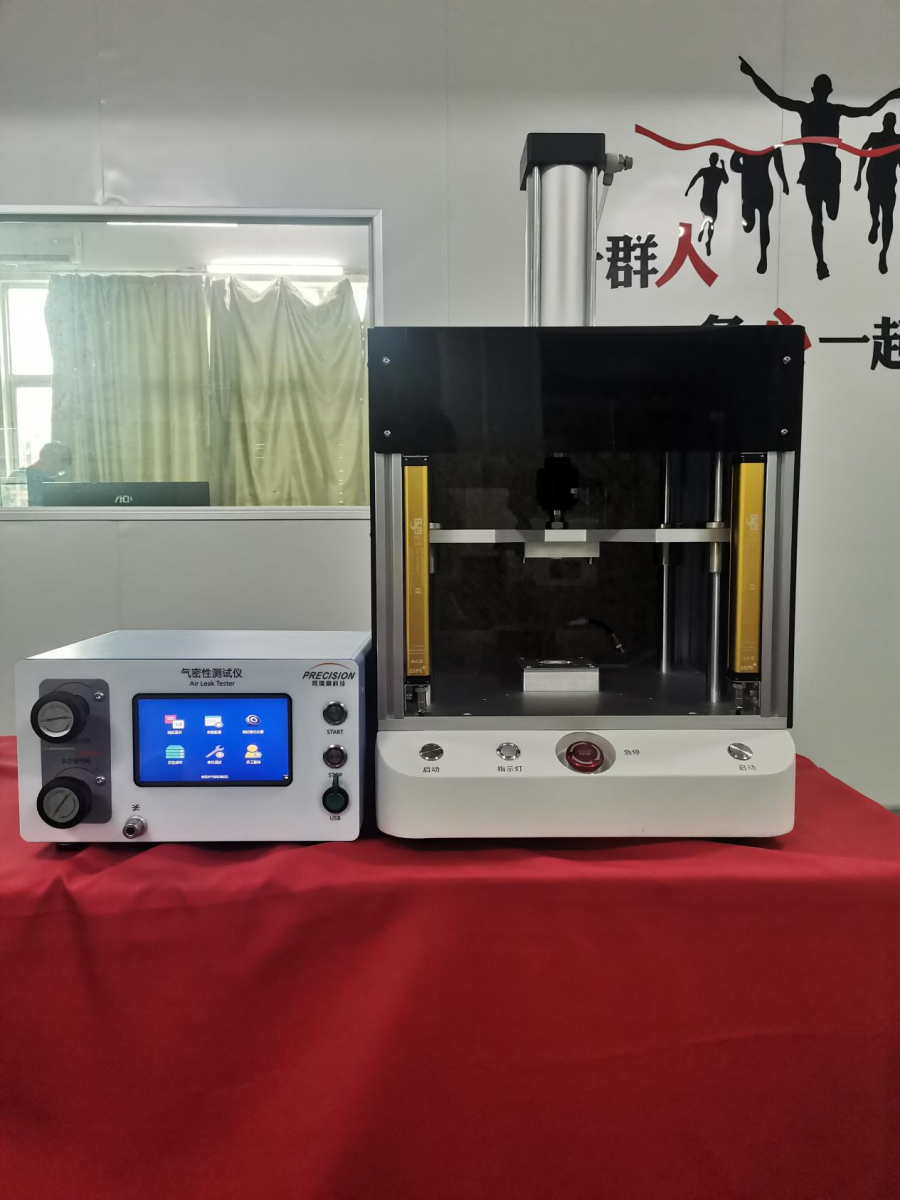

3. Air tightness test for electronic telescopes

Used for air tightness detection of electronic telescopes, which must meet the IP67 waterproof level requirements. This equipment adopts the volumetric test principle, which is mainly used for fully sealed products without inflation ports.

Other fully sealed products without inflation ports can be tested for air tightness using this equipment.

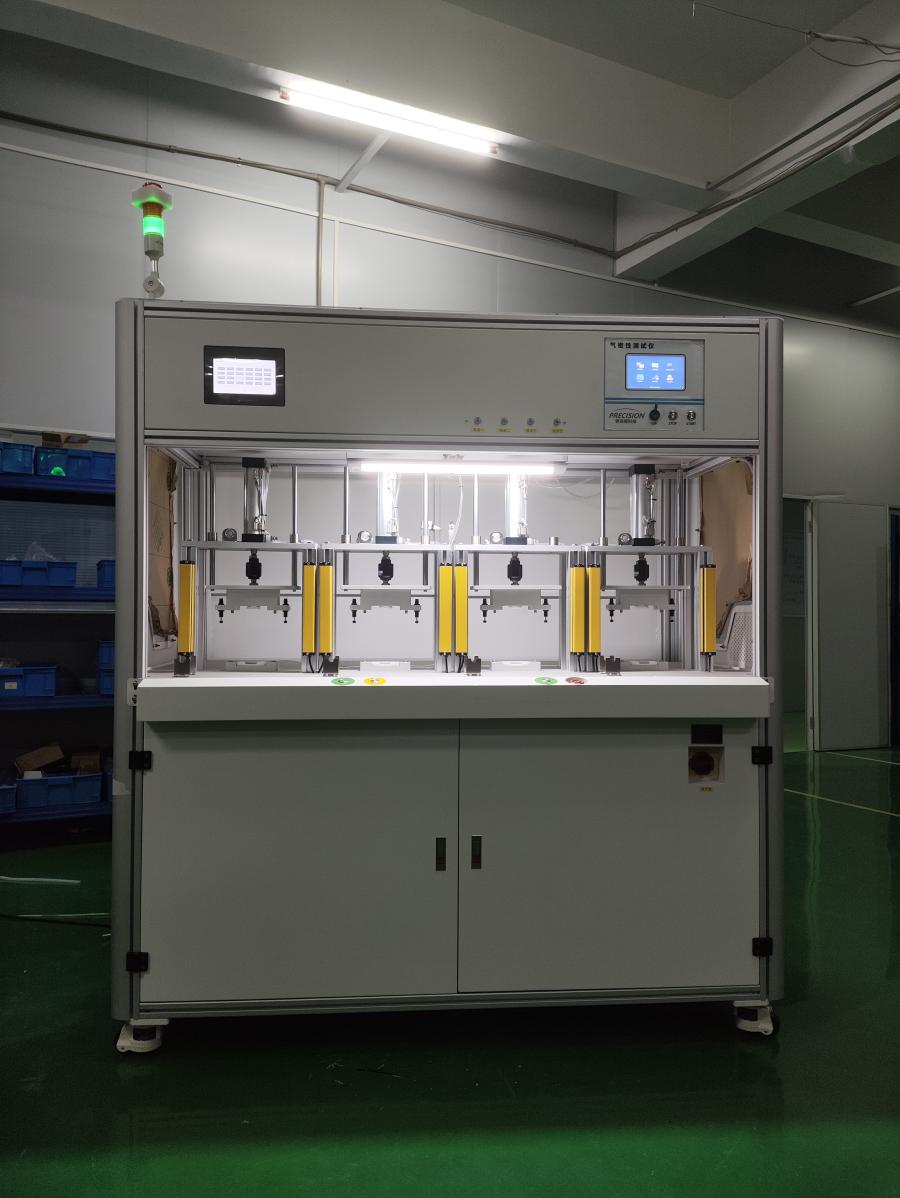

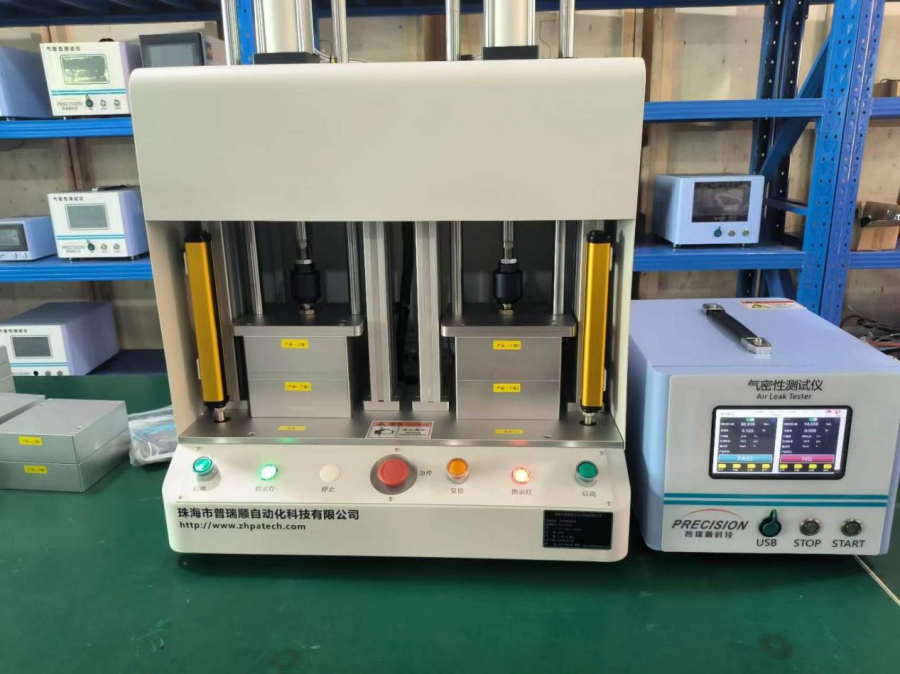

4. Air tightness test of automotive sensors

This equipment is a four-channel cabinet-type automotive sensor air tightness test equipment. It can test 4 products at a time, and each channel can determine the output test results separately.

The waterproof performance of automotive sensors and other parts is related to driving safety, so the air tightness test of some automotive parts requires full inspection. Multi-channel air tightness equipment effectively improves the detection efficiency.

5. Air tightness test of automotive reversing lens

Because the car reversing lens is exposed to the air for a long time, if the airtightness is poor, water vapor or rainy weather will affect the performance and clarity of the lens, causing inconvenience in driving.

This equipment is mainly used to test the airtightness of the car reversing lens. The test pressure is 300KPa, and the waterproof requirement is relatively high.

Other automotive parts can be tested for airtightness with this equipment.

6. Airtightness test of thermos cup

Thermos cups are generally designed with double-layer hollows to enhance the insulation effect and insulation time; if the thermos cup is not airtight, it will cause leakage and poor insulation effect.

This equipment is mainly used to test the airtightness of thermos cups, which meets the IP67 waterproof level requirements. The test position is mainly to see whether the double-layer joint welding position is welded well.

Other products such as smart water cups and thermos cups that have airtightness test requirements can be tested with this equipment.